Commonly Replaced Truck Parts in New Zealand Heavy Vehicles

Heavy vehicles in New Zealand operate in demanding conditions. Long highway distances, steep terrain, rural dust, coastal corrosion, and heavy payloads all contribute to wear and tear.

Understanding which truck parts most replaced helps fleet managers and owner operators are plan maintenance properly, reduce downtime, and avoid costly breakdowns.

While every truck operates differently, certain components consistently appear on replacement lists. The key is recognising normal wear items and addressing them before they become roadside failures.

Why Some Truck Parts Wear Faster in New Zealand Conditions

Distance and terrain

New Zealand transport routes often involve long distances combined with frequent gradients. Continuous braking on descents and heavy loads on inclines increase heat and stress on braking systems, suspension, and drivetrain components.

Operating environments

Rural roads expose trucks to dust and debris that accelerate wear on filters, seals, and moving parts. Coastal regions increase corrosion risk on electrical connections, exhaust systems, and fasteners. These environmental factors directly influence replacement frequency.

Load and driving style

Consistent heavy loads and harsh driving habits place additional strain on brakes, clutches, suspension, and steering components. Preventative servicing becomes even more important when vehicles operate at higher duty cycles.

Service Items vs Failure Parts

Some truck parts are designed to be replaced regularly. Filters, belts, brake linings, and hoses fall into this category. Replacing these on schedule protects more expensive systems.

Other parts are typically replaced after showing signs of wear, such as wheel bearings, alternators, or steering joints. Catching issues early during inspections reduces the risk of breakdowns and emergency repairs.

Brake System Components

Brake pads, shoes, and linings

Brake linings are among the most frequently replaced components because they are designed to wear. Replacement intervals vary depending on load and route profile, but ignoring worn linings can damage drums or rotors and increase repair costs.

Rotors, drums, and related hardware

Heat and friction gradually wear rotors and drums. If not addressed, surface scoring or thinning can compromise braking performance. Calipers and sliding hardware may also require replacement when corrosion or uneven wear develops.

Air brake components

Air chambers, valves, fittings, and air lines are common replacement items on heavy vehicles. Leaks or moisture in the system can affect braking efficiency and compliance, making regular inspection essential.

Suspension and Steering Wear Parts

Bushings and shock absorbers

Suspension bushings absorb constant vibration and load. Over time they degrade, affecting stability and tyre wear. Shock absorbers also lose effectiveness, particularly on uneven roads, increasing strain on other suspension components.

Steering linkages and joints

Tie rod ends and ball joints wear gradually through movement and load stress. Symptoms such as steering play or uneven tyre wear often signal replacement is needed. Because these parts directly affect safety, they should not be delayed once wear is identified.

Air suspension components

For trucks using air suspension, airbags and levelling valves frequently require replacement due to leaks or ageing rubber. When air suspension components fail, ride height and driveline alignment can be affected.

Tyres and Wheel End Components

Tyres

Tyres are one of the highest frequency replacement items. Wear is influenced by alignment, inflation, load distribution, and driving style. Monitoring wear patterns helps detect underlying issues early.

Bearings and seals

Wheel bearings and hub seals endure constant heat and rotation. Failure can lead to severe damage and downtime. Routine inspection and lubrication reduce the risk of major failure.

Wheel hardware

Studs and nuts may require replacement due to corrosion or repeated removal. Correct torque procedures help extend hardware life.

Filters, Hoses, and Cooling System Parts

Engine and fuel filters

Oil, fuel, and air filters are replaced routinely to protect engine components. In dusty or high utilisation environments, filters may require more frequent changes to maintain performance.

Hoses and clamps

Rubber hoses degrade from heat cycling and vibration. Coolant and air intake hoses are common failure points. Replacing ageing hoses proactively prevents unexpected overheating or breakdowns.

Cooling system components

Thermostats, radiator caps, and water pumps may require replacement over time. Cooling system failures can cause serious engine damage, making preventative checks critical.

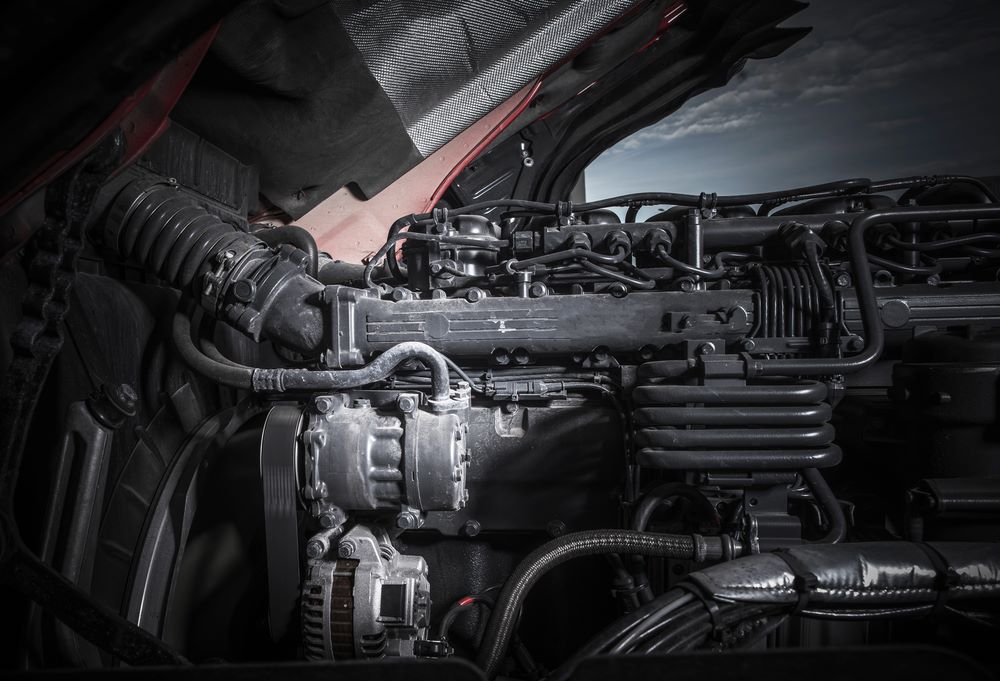

Engine and Drivetrain Components

Belts and tensioners

Drive belts and tensioners are high-wear items exposed to constant motion and heat. Replacing them during routine servicing prevents sudden loss of auxiliary systems.

Sensors and electrical engine parts

Modern heavy vehicles rely on sensors for engine management and emissions systems. Faulty sensors and corroded wiring are frequent replacement items, particularly in harsh environments.

Clutch components

Clutch wear depends heavily on operating conditions. Urban stop start work increases wear compared with long haul driving. Replacing worn clutch components before complete failure prevents more extensive transmission damage.

Electrical and Lighting Components

Batteries and charging systems

Batteries have a limited lifespan and are commonly replaced. Alternators and starter motors also wear over time, particularly in high utilisation fleets.

Lighting and connectors

Lights, trailer plugs, and wiring connectors often require replacement due to weather exposure and vibration. Maintaining clean, secure connections reduces recurring electrical faults.

Exhaust and Emissions Components

Exhaust mounts and flex joints

Exhaust components are exposed to heat and vibration. Mounts, clamps, and flex joints commonly wear and require replacement to prevent noise, leaks, or system damage.

Emissions related parts

Where fitted, emissions sensors and components can require periodic replacement. Early attention to warning lights helps avoid performance limitations or compliance issues.

Trailer and Coupling Parts

Fifth wheel and kingpin wear

In articulated combinations, fifth wheel components and kingpins experience significant stress. Regular inspection and lubrication reduce premature wear.

Trailer brakes and suspension

Trailer brake components, wheel bearings, and suspension parts often mirror the wear patterns of the prime mover. Consistent maintenance across both units reduces breakdown risk.

Spotting Wear Before It Becomes a Breakdown

Unusual noises, vibration, steering instability, and warning lights often indicate developing problems. Addressing these early can prevent secondary damage. Regular inspections tailored to actual operating conditions are more effective than relying solely on fixed service intervals.

High utilisation fleets may require shorter inspection cycles, while lower utilisation vehicles still need routine checks, particularly if operating in harsh environments.

Choosing Quality Truck Parts in New Zealand

Selecting quality truck parts is critical for reliability. Both genuine and high quality aftermarket components can be appropriate, depending on the application. The most important factors are fitment accuracy, durability, warranty support, and supplier reliability.

Parts availability and technical support also influence downtime. A supplier who can quickly identify the correct part and deliver promptly reduces lost operating time and improves maintenance efficiency.

Reducing Downtime With Smarter Parts Planning

The truck parts most replaced in New Zealand heavy vehicles are those exposed to friction, heat, load, and constant movement. Brakes, tyres, suspension joints, filters, hoses, electrical components, and wheel end parts consistently top the list.

Tracking wear trends within your fleet, maintaining preventative replacement schedules, and working with reliable suppliers helps reduce unexpected failures. With proper planning, routine part replacement becomes predictable maintenance rather than costly downtime, keeping trucks on the road and operations running efficiently.