The Ultimate Maintenance Checklist for Modern Diesel Vehicles

Modern diesel vehicles are built with advanced technologies that go far beyond the traditional diesel engines of the past. With stricter emissions laws and more complex engine systems, keeping these vehicles running efficiently requires more than the occasional oil change. This comprehensive maintenance checklist for modern diesel vehicles is designed to help fleet managers, diesel owners, and transport operators in New Zealand and Australia stay on top of their servicing needs—boosting performance, improving reliability, and ensuring emissions compliance.

Why Diesel Maintenance Has Changed

How Modern Diesel Vehicles Differ from Older Models

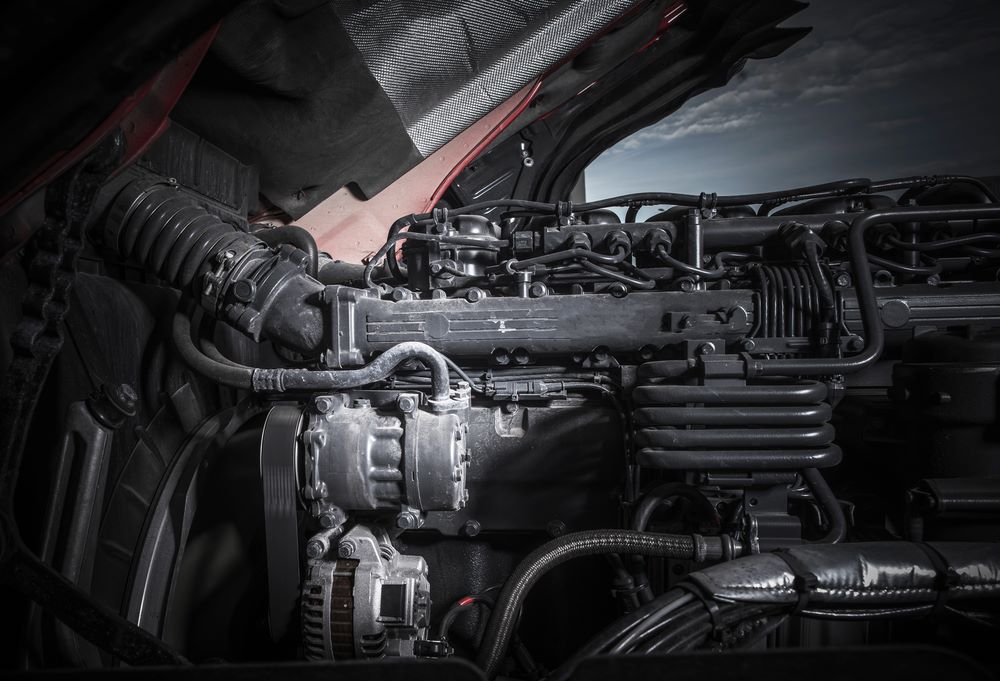

Today’s diesel vehicles come packed with sophisticated sensors, fuel management systems, and emissions control components that didn’t exist in earlier models. These upgrades have led to better fuel economy and reduced environmental impact, but they’ve also added layers of complexity to servicing. Basic maintenance is no longer enough—modern engines demand structured, proactive care.

The Role of Emissions Technology Like AdBlue and SCR

One of the biggest changes is the integration of Selective Catalytic Reduction (SCR) systems, which work in conjunction with AdBlue. These systems significantly lower harmful nitrogen oxide (NOx) emissions by converting them into nitrogen and water vapour. Regular AdBlue system maintenance is now a vital part of keeping diesel engines compliant and operating efficiently.

Why a Structured Maintenance Checklist Is Now More Critical Than Ever

Ignoring maintenance schedules can lead to expensive repairs, breakdowns, or even legal penalties due to emissions non-compliance. Following a structured checklist not only protects your vehicle but also ensures smooth, uninterrupted operation—especially for long-haul and commercial diesel fleets.

Routine Checks for Optimal Diesel Performance

Daily or Weekly Vehicle Walkarounds

Quick walkarounds are a simple but effective way to catch issues early. Look for fluid leaks beneath the vehicle, check that lights are working, and inspect the tires for signs of wear. Small visual cues often point to larger problems, making this habit a key part of daily operations.

Checking Fluid Leaks, Tire Wear, and Undercarriage Components

Look closely at fluid levels like oil and coolant, especially before long trips. Uneven tire wear can indicate alignment issues or underinflation, while damage to undercarriage components can signal previous impacts that need to be addressed.

Monthly Maintenance Must-Dos

Each month, take the time to inspect battery terminals for corrosion and ensure belts and hoses are secure and free of cracks. These components often degrade slowly and can go unnoticed until failure occurs.

Monitoring Exhaust Systems and Emissions Components

Modern diesel vehicles rely on clean, sealed exhaust systems to support aftertreatment processes. Check for rust, loose fittings, or sensor issues that could interfere with SCR or DPF functions.

Engine Health and Diesel Fuel System Maintenance

Oil Changes and Filter Replacements

Diesel engines typically require oil changes every 10,000 to 15,000 kilometres, depending on workload and operating conditions. Using high-quality oil and genuine diesel-rated filters ensures proper lubrication and protects the engine from premature wear.

Importance of Genuine Parts and Diesel-Rated Filters

Cheaper parts might save you money upfront but can cost more long-term. Genuine filters are designed to handle diesel-specific demands, including higher soot and particulate loads.

Diesel Fuel System Care

The fuel system is one of the most critical components to maintain. Water and contaminants can easily damage injectors, so it’s important to regularly service water separators and replace filters. Keeping the fuel system clean contributes directly to long-term diesel engine care.

Why Regular Fuel System Cleaning Improves Engine Life

Over time, injectors and fuel lines can build up deposits that reduce performance and fuel efficiency. Periodic cleaning helps restore spray patterns, improve combustion, and reduce strain on the engine.

Exhaust Aftertreatment and Emissions Control

SCR Systems and AdBlue Maintenance

SCR systems play a major role in diesel emissions compliance. They rely on AdBlue to reduce NOx levels in the exhaust. Topping up AdBlue is straightforward, but it must be done regularly—typically every 5,000 to 10,000 kilometres. Using high-quality AdBlue and monitoring usage helps prevent injector clogging or system warnings. If the AdBlue tank runs dry, many modern vehicles will refuse to start until it’s refilled, so it’s important to never ignore low-level warnings.

Signs of AdBlue System Faults and How to Prevent Them

If you notice dashboard alerts, reduced power, or unusual exhaust smells, your AdBlue system may be underperforming. Keep the system clean, top up the fluid as needed, and address faults promptly to avoid SCR failure and downtime.

DPF (Diesel Particulate Filter) Monitoring

The DPF captures soot from the exhaust and burns it off during regeneration. Issues arise when regeneration is interrupted—often due to repeated short trips. If left unchecked, the DPF can become clogged, resulting in reduced power and increased fuel use. Monitoring your DPF health and knowing when regeneration is or isn’t occurring is a smart way to prevent expensive repairs.

Transmission, Cooling, and Electrical Checks

Transmission and Drivetrain Servicing

The transmission must be checked regularly for smooth gear changes and proper fluid levels. Strange noises or delayed shifting are warning signs that should trigger an immediate inspection. Keeping the drivetrain in top condition is especially important for vehicles carrying heavy loads.

Cooling System Checks

Diesel engines operate at higher temperatures and are prone to overheating if the cooling system is compromised. Check the radiator for debris, confirm coolant levels are adequate, and make sure the thermostat is functioning correctly. Any failure here can result in costly engine damage.

Modern Diesel Electronics

Electronic Control Units (ECUs) manage many engine and emissions functions. Regular diagnostics help ensure sensors are reading accurately and that wiring looms are intact. Electrical faults can quickly cascade into bigger issues, especially in newer diesel models.

Tires, Brakes, and Suspension for Diesel Vehicles

Tre Pressure and Wear Patterns

Tires affect everything from safety to fuel efficiency. Make sure pressure levels are appropriate for your load and that wear patterns are even. Uneven wear often points to alignment issues or suspension problems.

How Tire Condition Affects Fuel Efficiency

Underinflated or worn tires increase rolling resistance, which forces the engine to work harder. Maintaining proper tire pressure is a simple step that can significantly improve fuel economy.

Brake Pads and Fluid

Heavy diesel vehicles demand strong braking systems. Check brake pads regularly and replace them before they wear too thin. Brake fluid should be flushed according to manufacturer recommendations to keep braking performance reliable.

ABS and Electronic Brake Systems in Newer Diesels

Modern braking systems often include ABS and traction control. These systems rely on sensors and electronic modules that should be checked periodically during diagnostics to ensure they’re functioning as intended.

Seasonal and Long-Haul Maintenance Considerations

Pre-Winter Diesel Preparation

Cold weather can introduce challenges like fuel gelling and slow starts. Switching to winter-grade diesel, testing glow plugs, and checking battery performance are key to keeping your vehicle reliable through the colder months.

Before Long Trips: Diesel Reliability Checks

Before heading off on extended journeys, especially across the varied terrain of New Zealand and Australia, conduct a thorough pre-trip inspection. Check fluid levels, top up AdBlue, clean filters, and carry spare parts like bulbs and fuses. Preparing in advance can prevent inconvenient breakdowns far from support.

Emergency Toolkits for Diesel Drivers

Having a toolkit with basics such as spanners, screwdrivers, torches, and spare belts or hoses can save the day in remote areas. Long-haul drivers especially benefit from being equipped to handle minor issues on the go.

Pro Tips for Extending the Life of Your Diesel Vehicle

Using High-Quality Diesel and Additives

Poor-quality fuel can lead to injector fouling and reduced performance. Investing in quality fuel and using additives when appropriate helps keep the combustion system clean and efficient.

Regular Diagnostics and Service History Logs

Routine scanning for faults, even in the absence of warning lights, helps catch minor issues before they develop. Keeping a detailed log of all servicing and maintenance also aids troubleshooting and supports vehicle resale value.

Partnering with a Trusted Diesel Specialist or Fleet Service Provider

A professional mechanic with experience in modern diesel systems is invaluable. They’ll not only keep your vehicle compliant with regulations but also advise on the best preventative maintenance practices for your particular model or fleet.

Stay Ahead with Preventative Maintenance

A structured maintenance checklist for modern diesel vehicles is more than just a routine—it’s a roadmap to longer vehicle life, better fuel economy, and compliance with increasingly strict emissions standards. By staying on top of diesel vehicle servicing, from AdBlue system maintenance to engine care and diagnostics, you’ll reduce downtime and avoid unexpected costs. Download or print this checklist to use with your own vehicle or fleet, and explore our other guides for more detailed maintenance insights and tools.